Post by geezerman35 on Jan 12, 2008 6:38:49 GMT -5

I'm still waiting for wheels from Perry's Resin for the AA/FA, finished Blue's T and have it shipped back to him. So, I grabbed the other 50 Ford convert. Don't exactly know where I'm headin on this, but I have a couple of ideas.

First,. I have the kit's big rear tires on a set of my homemade deep steelies. I then cut down two of the tires for the front. They are too small for the car to set off the ground using the lowered option and look crappy using the normal axle location.

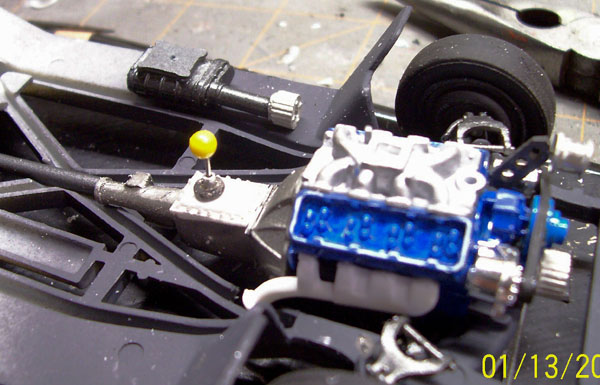

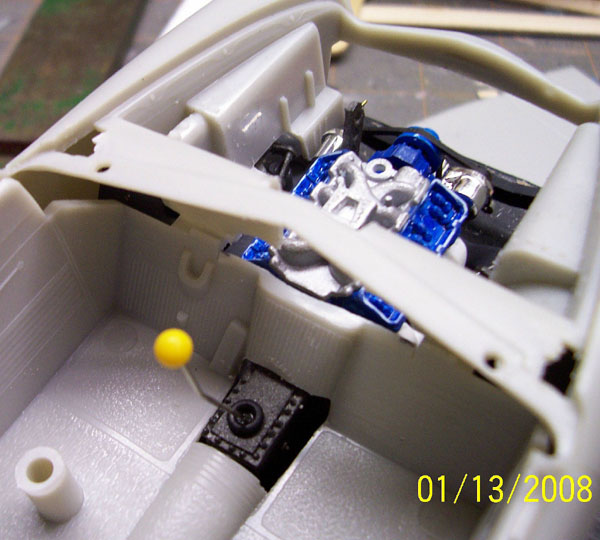

I'm not using the kit's Flathead that has the hole thru the block for the axle rod to pass thru. I'm using a blown engine with no hole.

This meant I had to fabricate some axles to attach the front wheels to. I ended up using 1/16" brass tubing to go into the holes in the backing plate of the wheel, and smaller brass rod that fits into the brass tubing to mount to the frame.

Using the top (lowered) holes with this smaller rod, leaves me some minimal tiebar clearance. The thickness of that scale ruler is all there is. about 1/32". Here is the front end, blocked square and the brass rods epoxy'd to the frame. I have used similar methods before to eliminate that full length metal axle passing thru the front. This, by the way, doesn't look too bad. I have the epoxy painted black and the upper A arms mount just above it.

I probably should have tried to cut some treads on the tires, but I figured I was pushing my luck just cutting them down that much on my Dremel.

.

.

So far, it seems I'll have a pretty good rake on this build,

First,. I have the kit's big rear tires on a set of my homemade deep steelies. I then cut down two of the tires for the front. They are too small for the car to set off the ground using the lowered option and look crappy using the normal axle location.

I'm not using the kit's Flathead that has the hole thru the block for the axle rod to pass thru. I'm using a blown engine with no hole.

This meant I had to fabricate some axles to attach the front wheels to. I ended up using 1/16" brass tubing to go into the holes in the backing plate of the wheel, and smaller brass rod that fits into the brass tubing to mount to the frame.

Using the top (lowered) holes with this smaller rod, leaves me some minimal tiebar clearance. The thickness of that scale ruler is all there is. about 1/32". Here is the front end, blocked square and the brass rods epoxy'd to the frame. I have used similar methods before to eliminate that full length metal axle passing thru the front. This, by the way, doesn't look too bad. I have the epoxy painted black and the upper A arms mount just above it.

I probably should have tried to cut some treads on the tires, but I figured I was pushing my luck just cutting them down that much on my Dremel.

.

. So far, it seems I'll have a pretty good rake on this build,

It's an interweb thing.....

It's an interweb thing.....